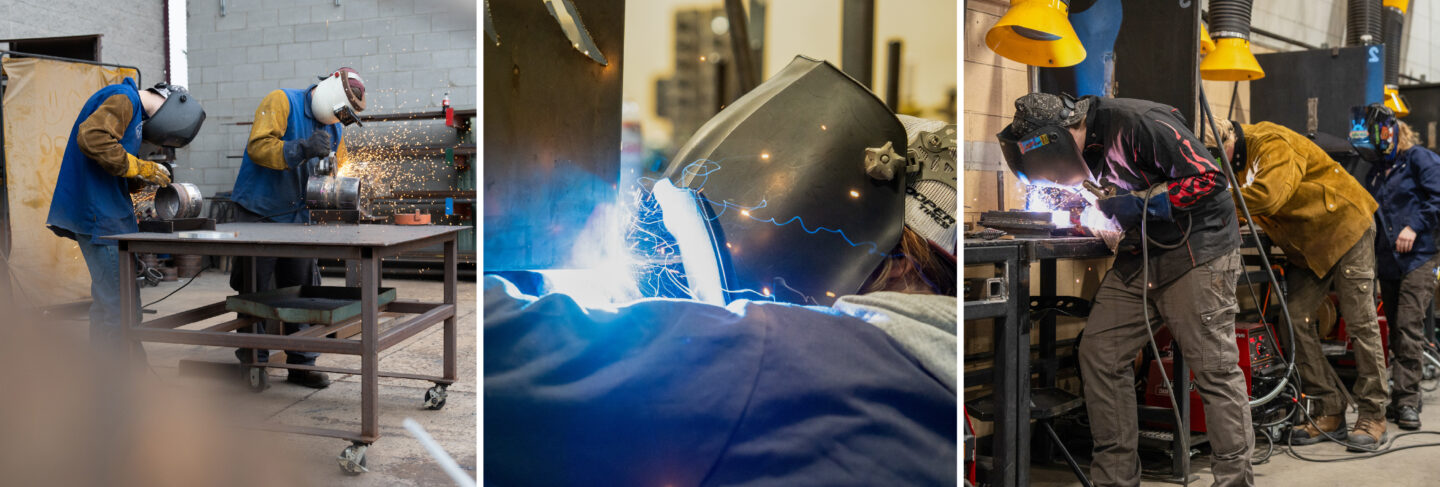

Welding (CTS, CAS, AAS)

With expert instructors, cutting-edge equipment and certifications that employers value, FVCC’s Welding program is here to meet your needs. Graduates with an FVCC welding degree or certificate have a wide range of career opportunities as welding technicians in fabrication and manufacturing, steel construction, mining, energy, petroleum, bridge construction and other production areas.

Students can choose from three options:

The welding instructors are super thorough and provide one-on-one support - they make class personal. The best part is I don't have to work to go through college because of scholarships, so I can focus on learning and not stressing about affording it.

Haily Mundel

Welding Student, Class of 2025

Students learn in a hands-on environment that builds strong foundational skills and allows them to gain specialized certifications and experience in a wide variety of welding applications. With support from industry partners and a focus on workforce preparation, our students are well-equipped to connect with local employers and thrive in a rapidly evolving industry.

Chris Sherman

Welding Instructor

Gabriel Dillon

Academic Advisor

Welding and Fabrication Technology (AAS, CAS)

Admission Guidelines

Proof of a score of 55 (Level 1) or higher in Intro/Beginning Algebra on the FVCC math Placement OR an official transcript proving “C-” or better in M065, its equivalent, or higher math course.

Program Information

After completing the program, students should be qualified for the following certifications:

- AWS D 1.1 in Limited Thickness Certification

- AWS D 1.1 in Unlimited Thickness Certification

- AWS D 1.1 Pipe Certification

Fees for this program are higher than average. Please see the program director for more details.

Opportunities after Graduation

Career opportunities offer a wide range of possibilities as a welding technician in the fabrication and manufacturing industries, steel construction, nondestructive testing and weld inspection, mining, energy, petroleum, bridge construction and other production areas.

Welding Technology (CTS)

Program Information

To earn this certificate, students must earn at least two American Welding qualifications as part of the WLDG 185 course curriculum. After completing the program, students should be qualified for the following certifications:

- SMAW 2G limited thickness or

- SMAW 3G limited thickness

- 3/8″ (mild steel)

Fees for this program are higher than average. Please see your advisor for more details.

Opportunities after Graduation

Career opportunities offer a wide range of possibilities as a welding technician in various production areas.